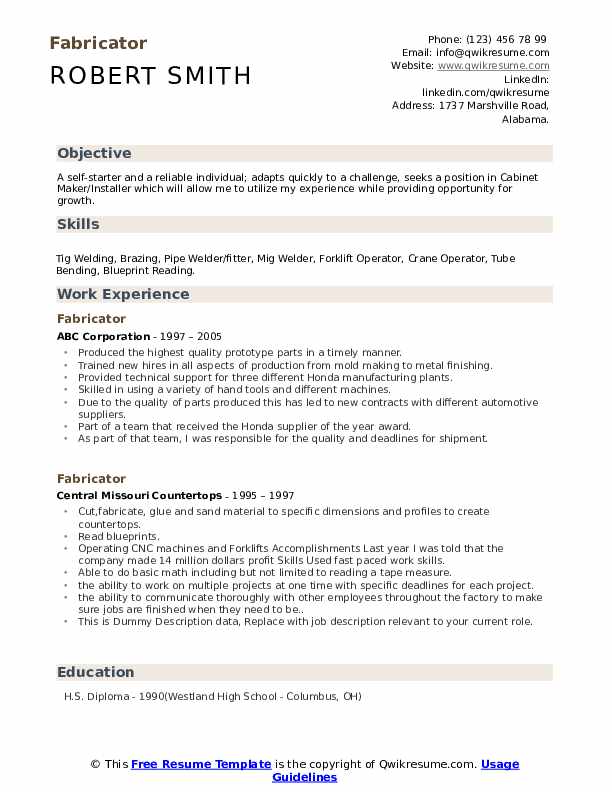

Fabricator Resume

Summary : As a Fabricator, responsible for Inspecting individual parts, assemblies, and installations for conformance to specifications and building codes, using measuring instruments such as calipers, scales, and micrometers.

Skills : Mastercam 2d, Solidworks.

Description :

- Planned and laid out work to meet production and schedule requirements.

- Set up and operated production equipment in accordance with current good manufacturing practices and standard operating procedures.

- Troubleshoot problems with equipment, devices, or products.

- Unloaded, picked, staged, and loaded products for shipping.

- Oversaw warehousing and storage practices and housekeeping.

- Transported goods from racks, shelves, and vehicles.

- Worked at a rapid pace to meet tight deadlines.

Experience

10+ Years

Level

Senior

Education

Diploma

Fabricator/Welder Resume

Objective : Qualified Laborer who stays current with public safety and security standards. Also dependable and reliable. Motivated to get along well with others and exceed expectations.

Skills : Mastercam 2d, Solidworks.

Description :

- Observed safety practices and procedures to maintain a safe and clean work environment.

- Bent, fitted and brazed pipes according to precise specifications.

- Drilled holes and compared templates to promote quality production.

- Unloaded and stored raw material deliveries.

- Met company standard times and individual productivity goals consistently.

- Lifted and moved items weighing over 50 pounds.

- Operated drill presses, milling machines and rivet safely and correctly.

Experience

2-5 Years

Level

Junior

Education

Certification

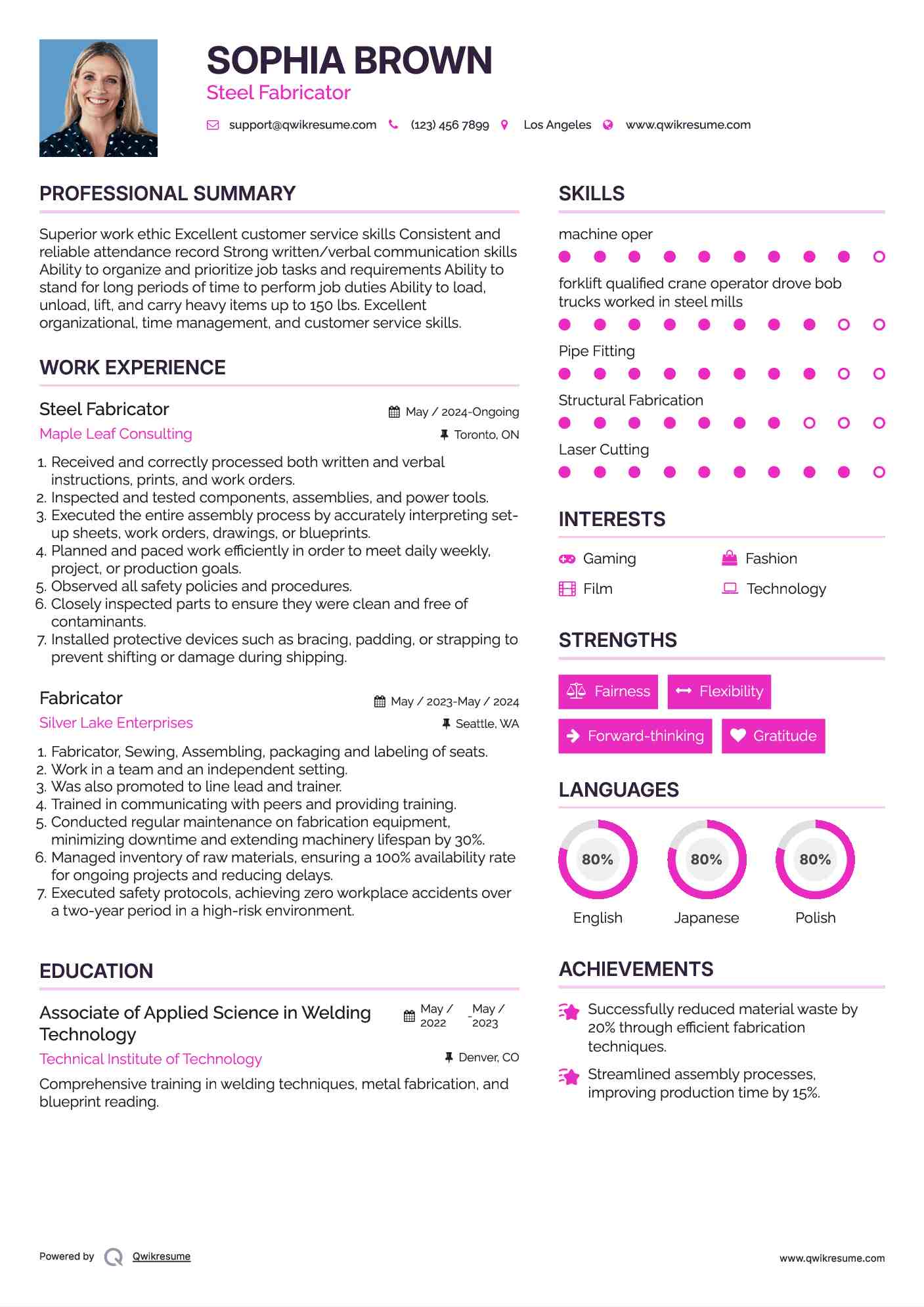

Steel Fabricator Resume

Objective : Superior work ethic Excellent customer service skills Consistent and reliable attendance record Strong written/verbal communication skills Ability to organize and prioritize job tasks and requirements Ability to stand for long periods of time to perform job duties Ability to load, unload, lift, and carry heavy items up to 150 lbs. Excellent organizational, time management, and customer service skills.

Skills : machine oper, forklift qualified crane operator drove bob trucks worked in steel mills.

Description :

- Received and correctly processed both written and verbal instructions, prints, and work orders.

- Inspected and tested components, assemblies, and power tools.

- Executed the entire assembly process by accurately interpreting set-up sheets, work orders, drawings, or blueprints.

- Planned and paced work efficiently in order to meet daily weekly, project, or production goals.

- Observed all safety policies and procedures.

- Closely inspected parts to ensure they were clean and free of contaminants.

- Installed protective devices such as bracing, padding, or strapping to prevent shifting or damage during shipping.

Experience

0-2 Years

Level

Entry Level

Education

Marketing/Business

Plastics Fabricator Resume

Objective : Capable of walking, bending, standing, and lifting items weighing up to 35 pounds without assistance, and over 35 pounds with assistance if required by the company. I am capable of standing, stooping, bending, climbing, and kneeling for an extending periods in an uncomfortable position. I am capable of working in hot or cold areas, as well as indoors and outdoors.

Skills : Computer Skills: Microsoft Word.

Description :

- Capabled of fabricating nylon material into a tow strap sling.

- Capabled of marking, cutting, and stitching a nylon sling into any length or size with an industrial sewing machine.

- Able to fabricate around sling with poly yarn and poly jackets.

- knowledgeable and responsible for making a sling to hold what is complied pull to pull strength on the tag, or suffer the consequence of someone overloading the sling and getting injured or killed if the sling is improperly fabricated by regulation.

- Capabled of fabricating chain, rope, and assist in fabricating wire rope (steel cable) into slings.

- Fabricated slings big enough to pull test of more than a quarter of a million pounds of pressure pull to pull.

- Most to all related to Oilfield Services.

Experience

2-5 Years

Level

Executive

Education

High School Diploma

Senior Fabricator Resume

Objective : Worked at several factories good people skills ran several types of machinery always been a loyal and dependable employee. Steady pace work interests me, a job that requires a little manual labor interest me.

Skills : service and maintenance of heavy and light equipment, Mechanically Inclined, basic math, Basic Computer Skills, Management Experience, Customer Service, 10-Key, hand tools, chemical applications.

Description :

- Participated in the aluminum extrusion production process.

- Responsible for assembly, fabrication, and packing of aluminum.

- Involves the accurate control of inventory, quality, and measurement.

- Required the involvement and correct use of tools, blueprints, and machinery.

- Extensive labor and routinely with a partner; teamwork essential.

- Brought out the maintenance of a clean working environment.

- Commended at times for the good level of workflow and production.

Experience

2-5 Years

Level

Executive

Education

Diploma

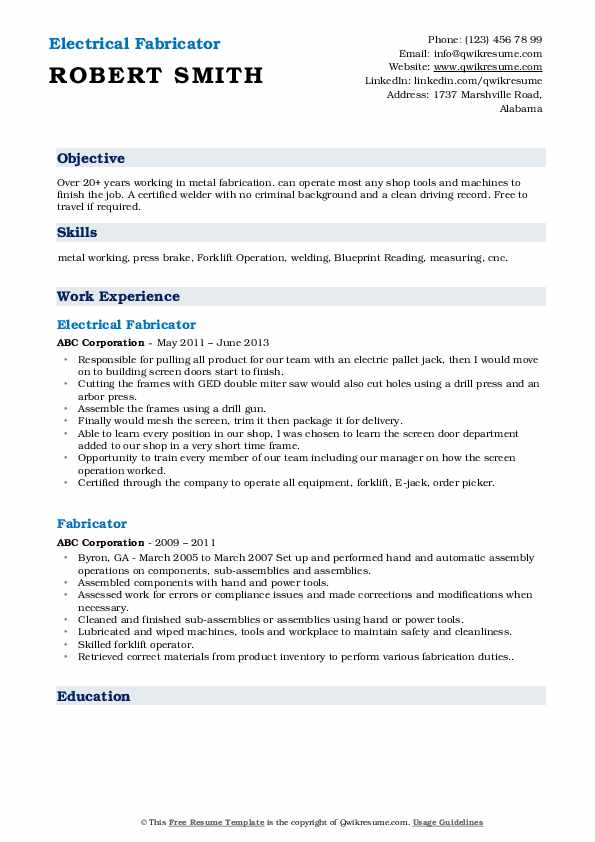

Electrical Fabricator Resume

Headline : Over 20+ years working in metal fabrication. can operate most any shop tools and machines to finish the job. A certified welder with no criminal background and a clean driving record. Free to travel if required.

Skills : metal working, press brake, Forklift Operation, welding, Blueprint Reading, measuring, cnc.

Description :

- Responsible for pulling all products for our team with an electric pallet jack, then I would move on to building screen doors from start to finish.

- Cutting the frames with GED double miter saw would also cut holes using a drill press and an arbor press.

- Assemble the frames using a drill gun.

- Finally would mesh the screen, trim it then package it for delivery.

- Able to learn every position in our shop, I was chosen to learn the screen door department added to our shop in a very short time frame.

- Opportunity to train every member of our team including our manager on how the screen operation worked.

- Certified through the company to operate all equipment, forklift, E-jack, order picker.

Experience

5-7 Years

Level

Executive

Education

Diploma

Custom Fabricator Resume

Objective : Quick Learner, dependable and have the ability to multitask. Hardworking individual, friendly, easy to get along with, and willing to learn new things. Good communication, written, and listening skills. High-temp equipment experience. Willing to work any shifts and overtime as needed. Machine operator. Loading trucks and lifting heavy boxes. Quick Learner Hard worker Multitask Dependable Team player Communication Skills.

Skills : Inventory Management, Heavy Equipment Operation, Computer Savvy.

Description :

- Verified conformance of workpieces to specifications by using squares, rulers and measuring tapes.

- Aligned and fitted parts according to specifications by using jacks, turnbuckles, wedges, drift pins, pry bars, and hammers.

- Ability to use move parts into position, manually or with hoists, cranes or forklift.

- Set up and operated fabricating machines, such as brakes, shears, grinders, and drill presses, to bend, cut, form, punch, and drill or otherwise form and assemble metal components.

- Set up jigs, and fixtures for drilling of girders.

- Removed high spots and cut bevels, using hand files, portable grinders and cutting torches.

- Used steel shoot blaster to remove scale from girders.

Experience

2-5 Years

Level

Junior

Education

High School Diploma

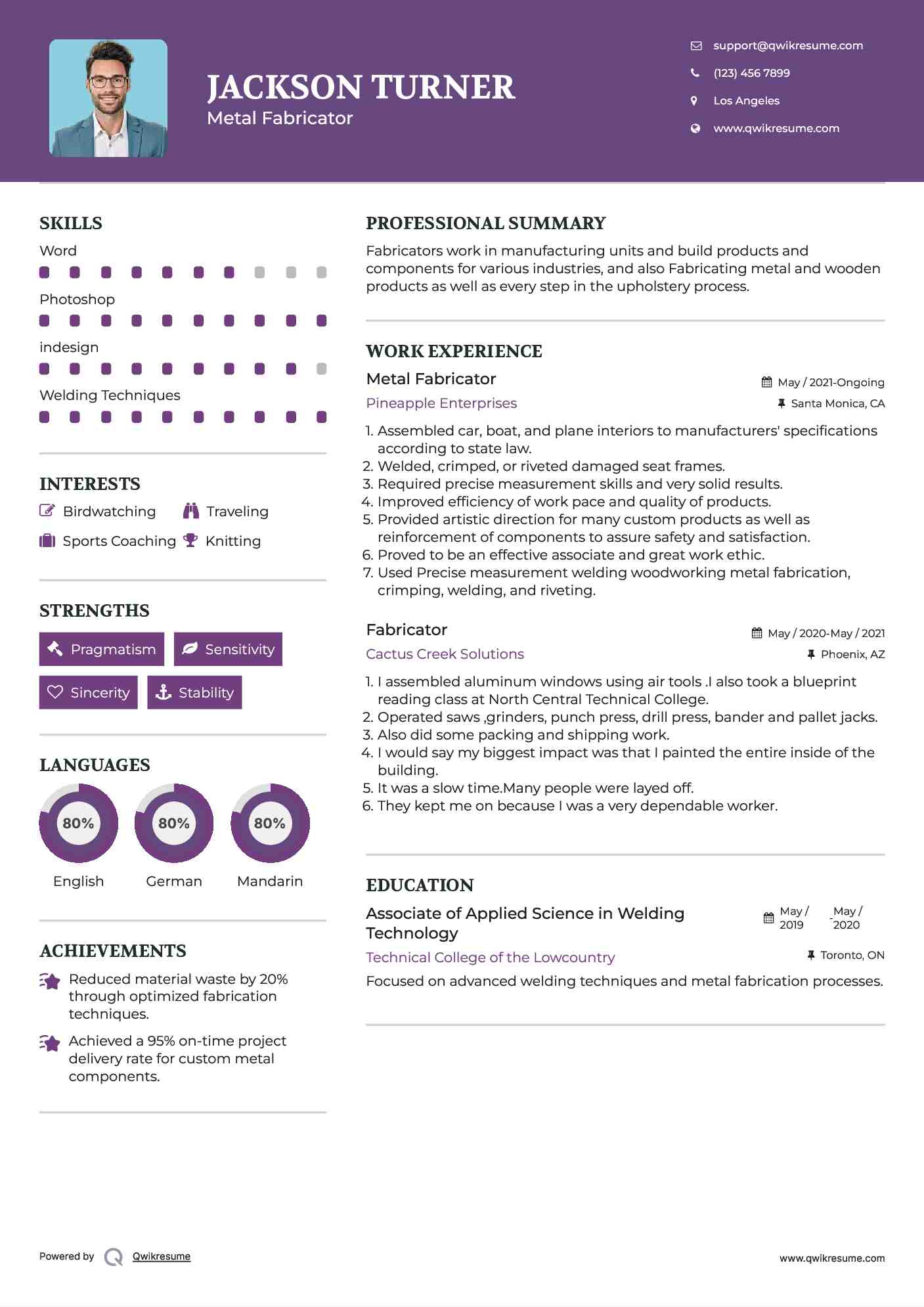

Metal Fabricator Resume

Objective : Fabricators work in manufacturing units and build products and components for various industries, and also Fabricating metal and wooden products as well as every step in the upholstery process.

Skills : Word, Illustrator, Photoshop, indesign.

Description :

- Assembled car, boat, and plane interiors to manufacturers' specifications according to state law.

- Welded, crimped, or riveted damaged seat frames.

- Required precise measurement skills and very solid results.

- Improved efficiency of work pace and quality of products.

- Provided artistic direction for many custom products as well as reinforcement of components to assure safety and satisfaction.

- Proved to be an effective associate and great work ethic.

- Used Precise measurement welding woodworking metal fabrication, crimping, welding, and riveting.

Experience

2-5 Years

Level

Junior

Education

Education

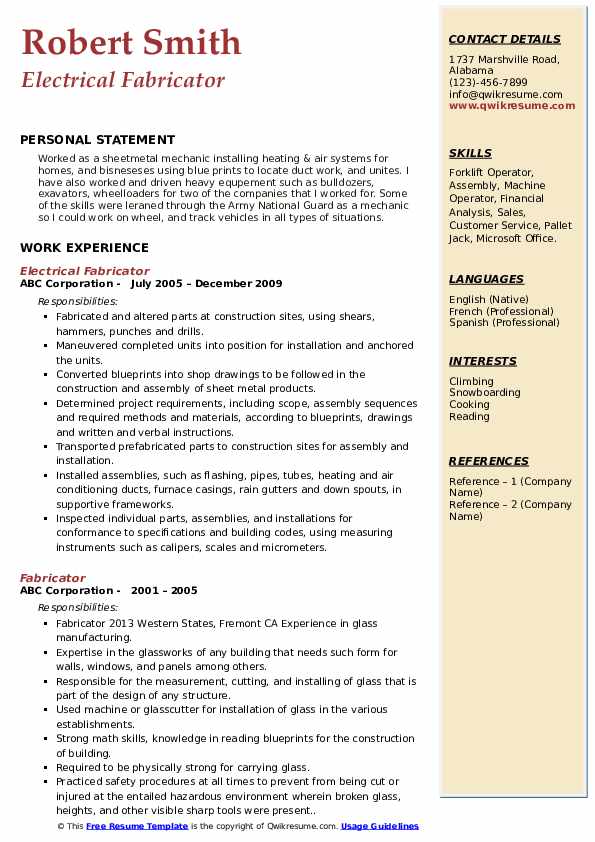

Electrical Fabricator Resume

Objective : Worked as a sheet metal mechanic installing heating & air systems for homes, and businesses using blueprints to locate ductwork, and units. I have also worked and driven heavy equipment such as bulldozers, excavators, wheel loaders for two of the companies that I worked for. Some of the skills were learned through the Army National Guard as a mechanic so I could work on wheel, and track vehicles in all types of situations.

Skills : Forklift Operator, Assembly, Machine Operator, Financial Analysis, Sales, Customer Service, Pallet Jack, Microsoft Office.

Description :

- Fabricated and altered parts at construction sites, using shears, hammers, punches, and drills.

- Maneuvered completed units into position for installation and anchored the units.

- Converted blueprints into shop drawings to be followed in the construction and assembly of sheet metal products.

- Determined project requirements, including scope, assembly sequences, and required methods and materials, according to blueprints, drawings, and written and verbal instructions.

- Transported prefabricated parts to construction sites for assembly and installation.

- Installed assemblies, such as flashing, pipes, tubes, heating, and air conditioning ducts, furnace casings, rain gutters, and downspouts, in supportive frameworks.

- Fastened seams and jointed together with welds, bolts, cement, rivets, solder, caulks, metal drive clips, and bonds in order to assemble components into products and to repair sheet metal items.

Experience

2-5 Years

Level

Junior

Education

Diploma

Tool Fabricator Resume

Objective : To obtain a stable full-time hov that will give me the opportunity to further my extensive experience in the service and warehouse industry. Highly experienced in customer service and inventor duty types. I am able to handle a high volume of customers in a fast-paced environment, with minimum supervision, while maintaining an emphasis on the highest quality of consumer service. I have excellent listening skills, oral and written communications.

Skills : Inventory Management, GANA Blue Print & Estimating Course, 20+ Yrs. Fork Lift Exp., 5+ Yrs. Overhead Crane Exp.

Description :

- Assembled or fabricated metal frameworks for windows or doors to be fitted with glass panels, using hand tools.

- Fabricated metal sashes and moldings for glass installation, using aluminum or steel framing.

- Glazed glass panes into metal sashes or frames with vinyl or moldings, adding weather seals or putty around pane edges to seal joints.

- Installed, repaired, and replaced glass and glass substitutes, such as plastic and aluminum, in the interior or exterior framing.

- Cut, assembled, fitted, and attached metal-framed glass enclosures for skylights and other structures.

- Loaded completed pre-glazed units into racks or crates and load completed racks onto trailers for shipment.

- Strapped down and tarp-loaded trailers for storage or shipment.

Experience

2-5 Years

Level

Executive

Education

Diploma

Fabricator Assistant Resume

Summary : Commercial and residential, 9 months of commercial and residential plumbing. About 8-10 months welding, first black iron for grease duct and storm shelters. Then stainless steel for a food production factory. Can operate forklift.

Skills : Commercial Drivers License.

Description :

- Checked for lining cracks, runbacks, receded mortar joints, softened bricks, and brick spotting.

- Provided an inspection report outlining the work done and notations on areas that should be watched on subsequent turnarounds.

- Repaired scope ranges from individual tube replacement to complete disassembly and rebuilding of the bundle.

- Installed and applied corrosion-resistant masonry lining which adds complete stability to prevent corrosion of vessels.

- Provided graphite heat exchanger maintenance by sometimes installing new internal baffle material, a distribution belt at the inlet nozzle, improvement of gaskets and packing, and tube sheet encasement.

- Provided common labor around the work areas as seen fit or needed to ensure the safety of all workers.

- Reported to and receives assignments, instructions, and direction from the Foreman or General Foreman.

Experience

7-10 Years

Level

Management

Education

Risk Management

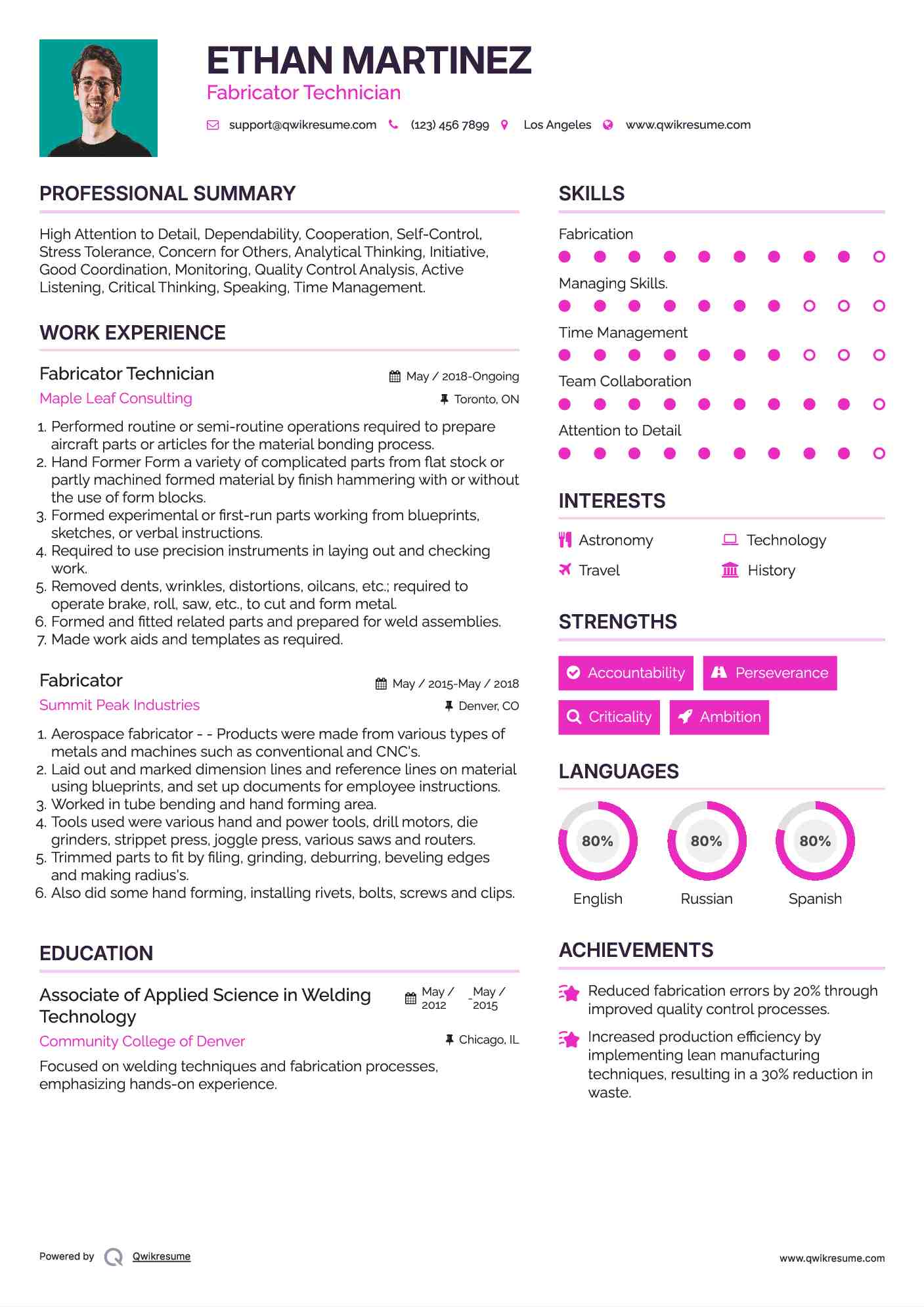

Fabricator Technician Resume

Summary : High Attention to Detail, Dependability, Cooperation, Self-Control, Stress Tolerance, Concern for Others, Analytical Thinking, Initiative, Good Coordination, Monitoring, Quality Control Analysis, Active Listening, Critical Thinking, Speaking, Time Management.

Skills : Fabrication, Managing Skills..

Description :

- Performed routine or semi-routine operations required to prepare aircraft parts or articles for the material bonding process.

- Hand Former Form a variety of complicated parts from flat stock or partly machined formed material by finish hammering with or without the use of form blocks.

- Formed experimental or first-run parts working from blueprints, sketches, or verbal instructions.

- Required to use precision instruments in laying out and checking work.

- Removed dents, wrinkles, distortions, oilcans, etc.; required to operate brake, roll, saw, etc., to cut and form metal.

- Formed and fitted related parts and prepared for weld assemblies.

- Made work aids and templates as required.

Experience

7-10 Years

Level

Management

Education

Diploma

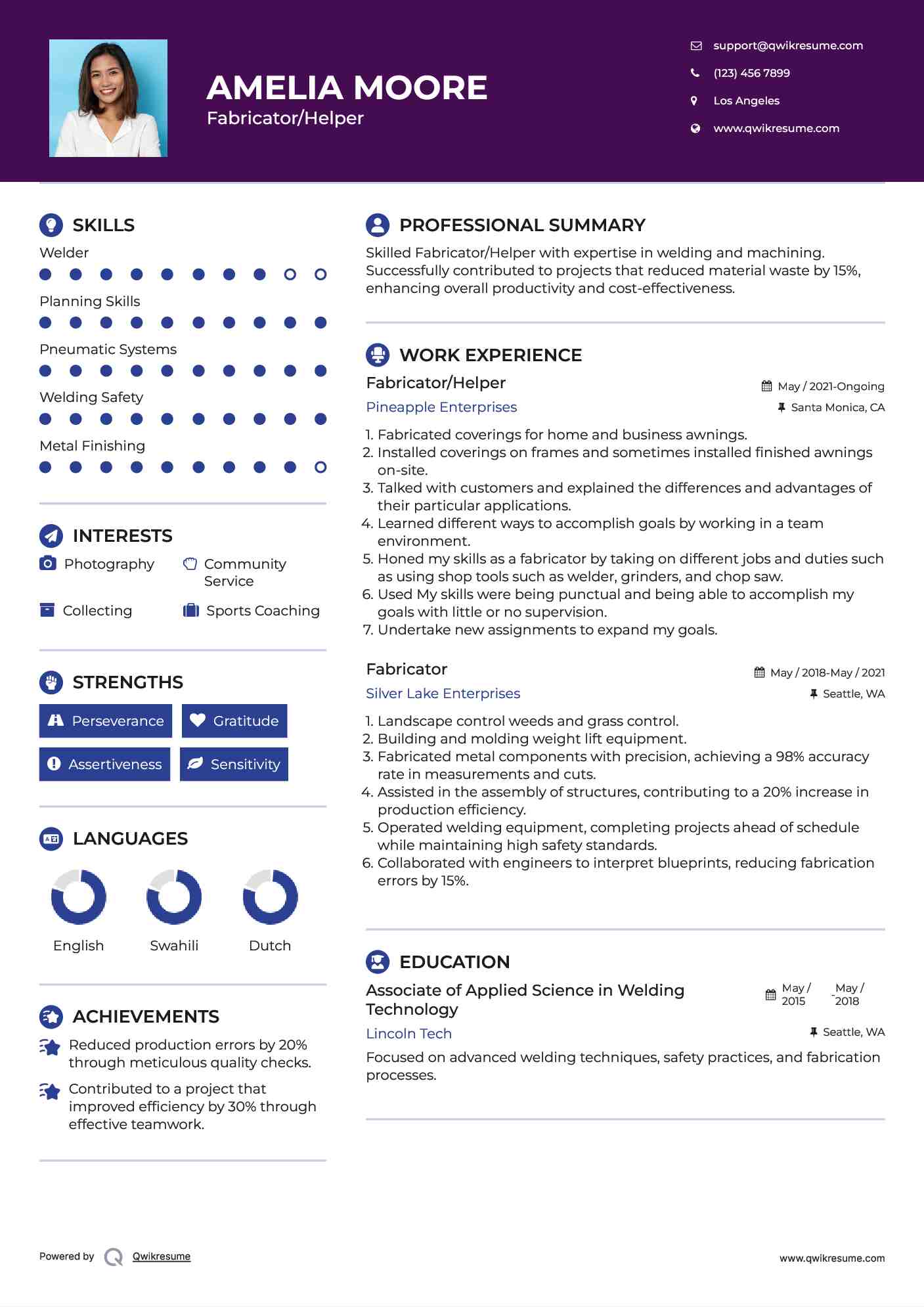

Fabricator/Helper Resume

Headline : To pursue and maintain a highly rewarding career. To obtain employment in a challenging but rewarding work environment where I can utilize my skills and knowledge efficiently to gain knowledge for growth in and for the company.

Skills : Welder, Planning Skills.

Description :

- Fabricated coverings for home and business awnings.

- Installed coverings on frames and sometimes installed finished awnings on-site.

- Talked with customers and explained the differences and advantages of their particular applications.

- Learned different ways to accomplish goals by working in a team environment.

- Honed my skills as a fabricator by taking on different jobs and duties such as using shop tools such as welder, grinders, and chop saw.

- Used My skills were being punctual and being able to accomplish my goals with little or no supervision.

- Undertake new assignments to expand my goals.

Experience

5-7 Years

Level

Executive

Education

High School Diploma

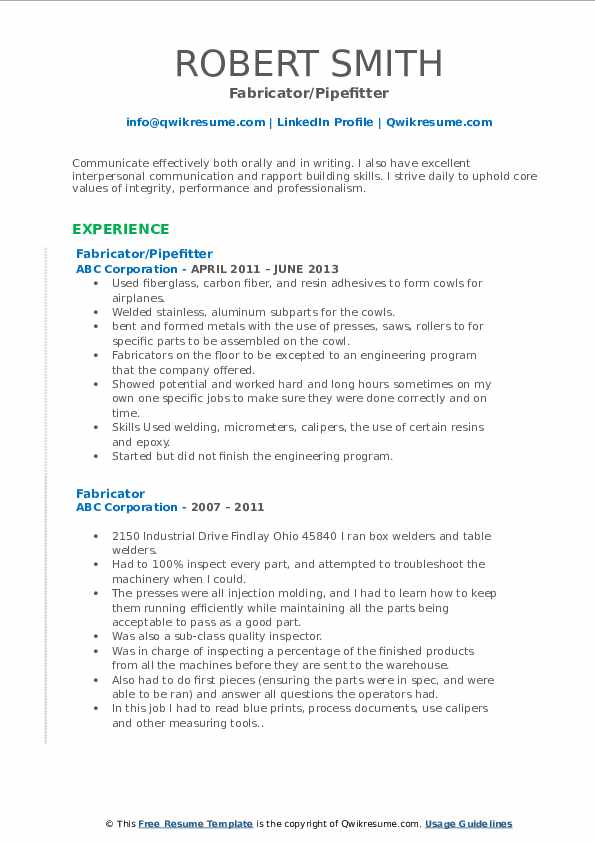

Fabricator/Pipefitter Resume

Objective : Communicate effectively both orally and in writing. I also have excellent interpersonal communication and rapport-building skills. I strive daily to uphold core values of integrity, performance, and professionalism.

Skills : Welding, Blueprint Reading, Fabricator.

Description :

- Used fiberglass, carbon fiber, and resin adhesives to form cowls for airplanes.

- Welded stainless, aluminum subparts for the cowls.

- bent and formed metals with the use of presses, saws, rollers to for specific parts to be assembled on the cowl.

- Fabricators on the floor to be excepted to an engineering program that the company offered.

- Showed potential and worked hard and long hours sometimes on my own one specific jobs to make sure they were done correctly and on time.

- Skills Used welding, micrometers, calipers, the use of certain resins and epoxy.

- Started but did not finish the engineering program.

Experience

0-2 Years

Level

Entry Level

Education

Bachelor's

Lead Fabricator Resume

Objective : To use my skills and experience and obtain the position of Metal Fabricator. Hands-on experience in maintaining and repairing with help of welding tools.

Skills : Forklift Certified by OSHA.

Description :

- Skilled trade demanding a strong understanding of technology, science, and engineering.

- Demonstrated ability to read blueprints, perform preventive maintenance, and regulatory compliance.

- Manufacturing steel components of Bobcat equipment through the operation of brake and punch presses, lasers, saws, sheers, and various machining equipment.

- Take measurements of parts fabricated using various engineering tools to ensure accuracy according to specifictions defined in blueprints.

- Write computer programs for new parts and make adjustments to existing programs to produce quality parts with a limited amount of waste.

- Collaborate with peers to develop efficient operating programs for new parts and analize data.

- Actively involved in OSHA safety training, Behavior-based safety introduction in the workforce and LEAN training.

Experience

2-5 Years

Level

Executive

Education

Diploma

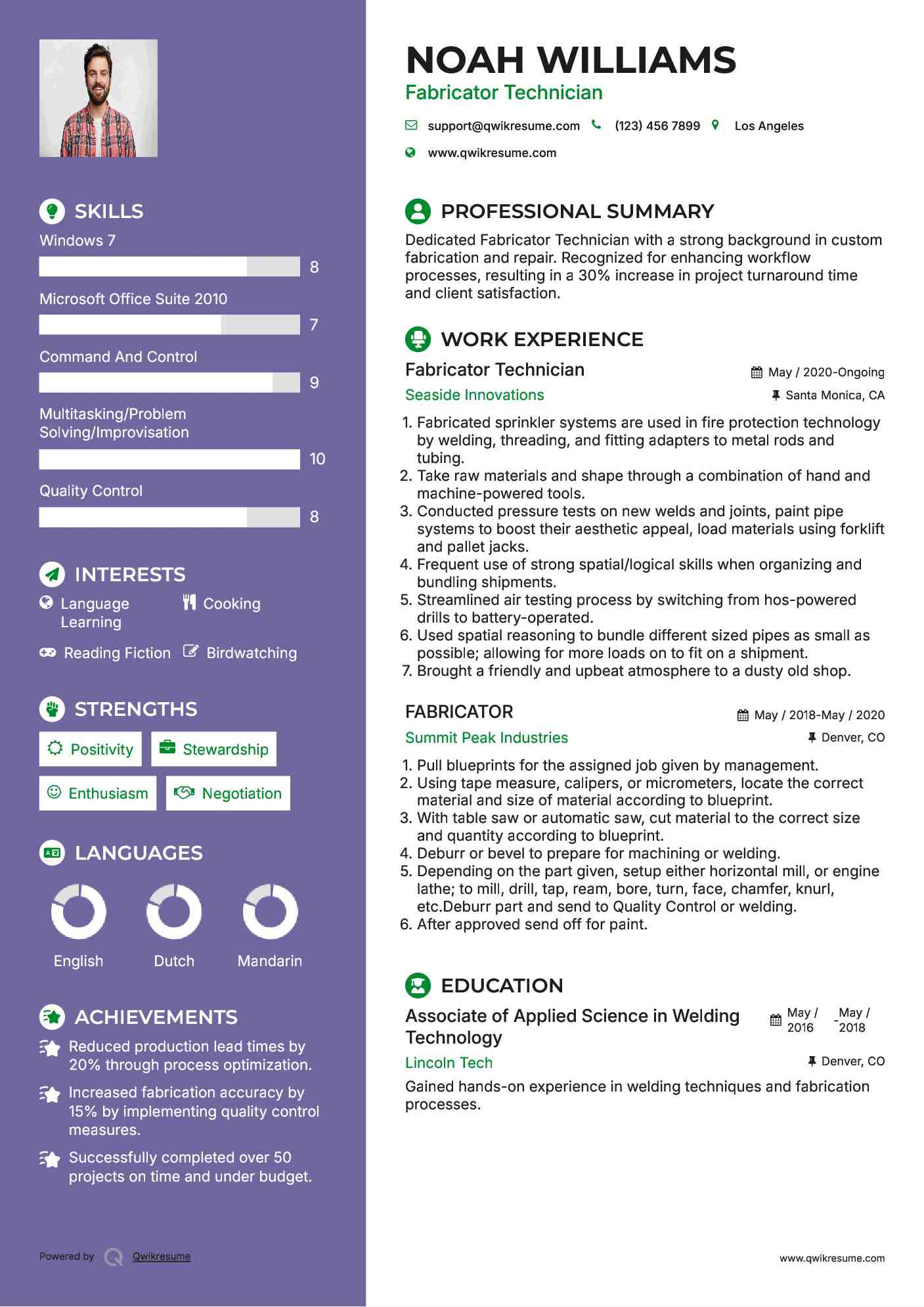

Fabricator Technician Resume

Headline : Self-motivated, and how to follow as well as lead. I can learn systems or operations with very little guidance and I bring positive upbeat energy to my workplace. I'm a determined and steadfast worker yet still like to form bonds and enjoy my time at work.

Skills : Windows 7, Microsoft Office Suite 2010, Command And Control, Multitasking/Problem Solving/Improvisation.

Description :

- Fabricated sprinkler systems are used in fire protection technology by welding, threading, and fitting adapters to metal rods and tubing.

- Take raw materials and shape through a combination of hand and machine-powered tools.

- Conducted pressure tests on new welds and joints, paint pipe systems to boost their aesthetic appeal, load materials using forklift and pallet jacks.

- Frequent use of strong spatial/logical skills when organizing and bundling shipments.

- Streamlined air testing process by switching from hos-powered drills to battery-operated.

- Used spatial reasoning to bundle different sized pipes as small as possible; allowing for more loads on to fit on a shipment.

- Brought a friendly and upbeat atmosphere to a dusty old shop.

Experience

5-7 Years

Level

Consultant

Education

Bachelors

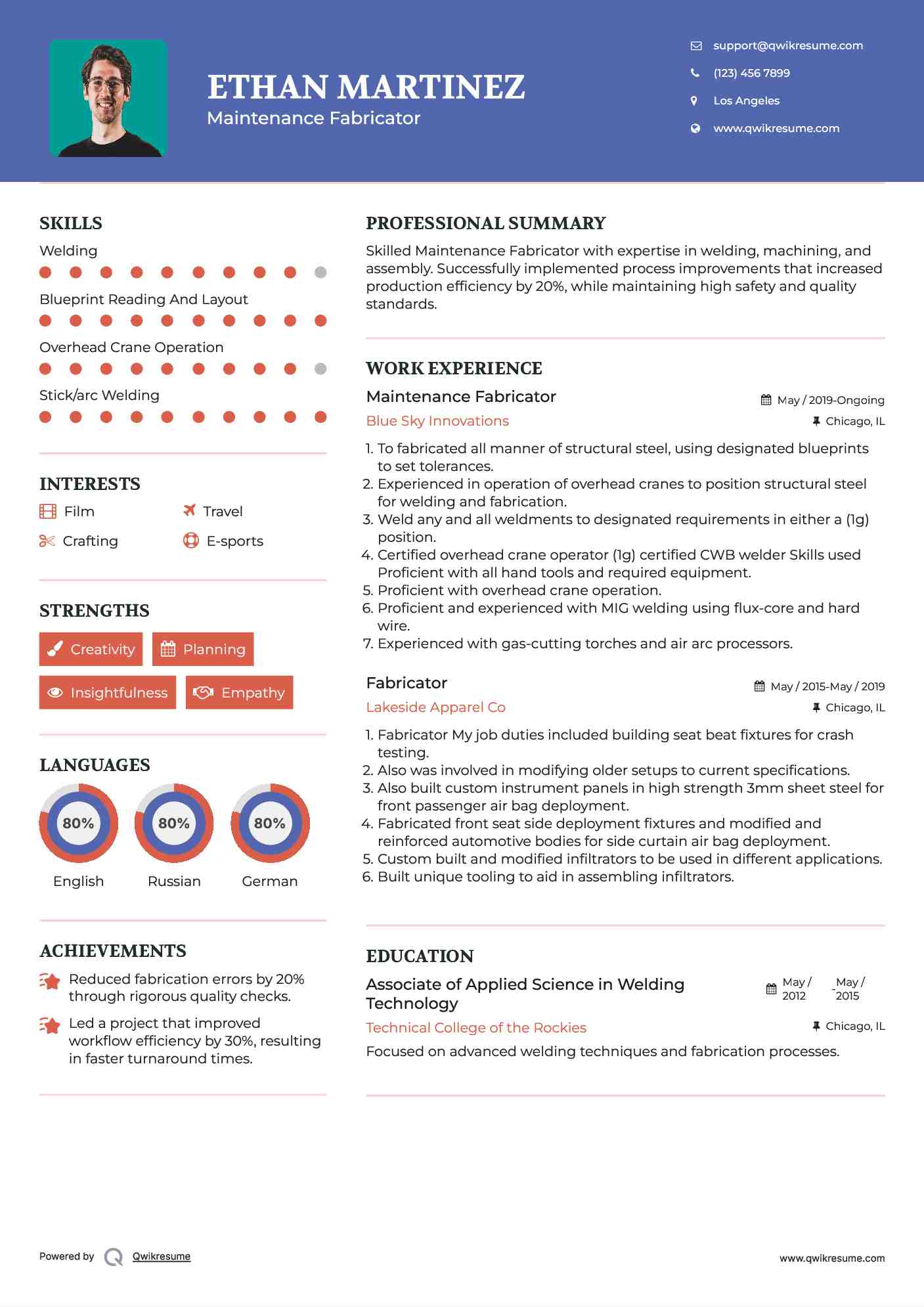

Maintenance Fabricator Resume

Summary : To acquire a challenging career with a solid company, while utilizing the opportunities provided to me and to continue developing my skills within the company. Bring forth my leadership skills and improve organizational ability to exceed corporate goals. Provide a Team atmosphere to all employees and corporate leadership.

Skills : Welding, Welding, Blueprint Reading And Layout, Overhead Crane Operation, Stick/arc Welding.

Description :

- To fabricated all manner of structural steel, using designated blueprints to set tolerances.

- Experienced in operation of overhead cranes to position structural steel for welding and fabrication.

- Weld any and all weldments to designated requirements in either a (1g) position.

- Certified overhead crane operator (1g) certified CWB welder Skills used Proficient with all hand tools and required equipment.

- Proficient with overhead crane operation.

- Proficient and experienced with MIG welding using flux-core and hard wire.

- Experienced with gas-cutting torches and air arc processors.

Experience

7-10 Years

Level

Management

Education

Business Administration

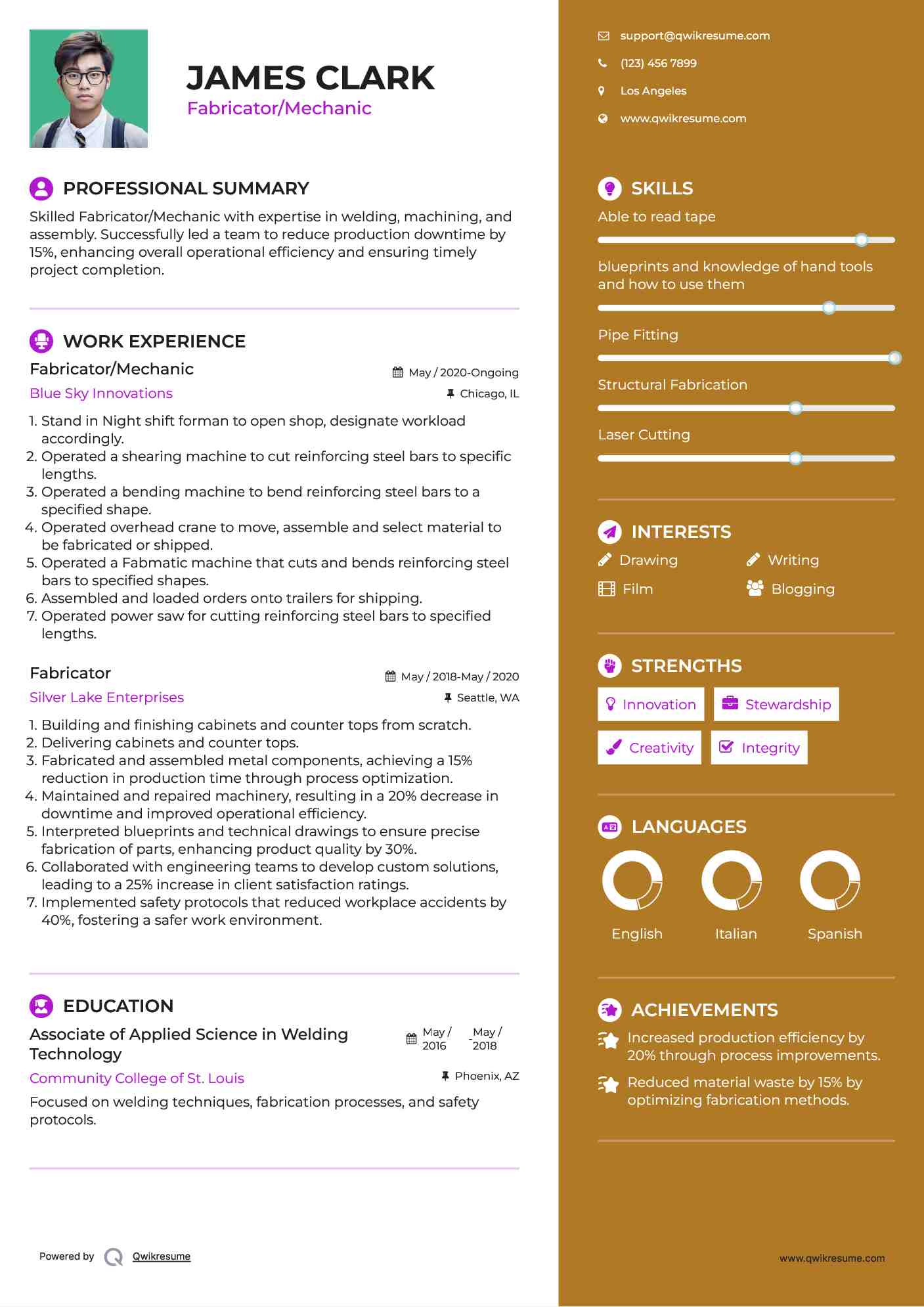

Fabricator/Mechanic Resume

Headline : To obtain a challenging position with a commercial or residential development company, are any employment in the St. Louis Metropolitan area to further my career while also advancing in the skills that I have already obtained.

Skills : Able to read tape, blueprints and knowledge of hand tools and how to use them.

Description :

- Stand in Night shift forman to open shop, designate workload accordingly.

- Operated a shearing machine to cut reinforcing steel bars to specific lengths.

- Operated a bending machine to bend reinforcing steel bars to a specified shape.

- Operated overhead crane to move, assemble and select material to be fabricated or shipped.

- Operated a Fabmatic machine that cuts and bends reinforcing steel bars to specified shapes.

- Assembled and loaded orders onto trailers for shipping.

- Operated power saw for cutting reinforcing steel bars to specified lengths.

Experience

5-7 Years

Level

Executive

Education

Dipolma

Fabricator Specialist Resume

Summary : Find employment with a company that values hard work and room to grow. Attended The Fab School. Looking for work full time. Mig tig stick welding(alum.,s.s., etc), blueprints, fabrication, tube bending, plasma, mill, and lathe.

Skills : Machine Operator, Painting.

Description :

- Cut steel, sheet metal, and wood to exact measurement.

- Operated big welder (millermatic 210/110) push-pull and stack dimes beads.

- Age sheet metal panels using patina, paint, and clear coat end product.

- Quality control check and package for shipping.

- End product is custom-made vintage industrial furniture.

- Ability to be the go-to guy for rush orders and VIP customers.

- Showed up every day, always bring shop morale up.

Experience

7-10 Years

Level

Management

Education

BSIS Certificate

Structural Fabricator Resume

Objective : Skilled at quickly learning new processes, technologies, and machinery. Self-motivated with strong organizational and time management abilities. BluePrint Reading Customer Service Fabrication.

Skills : Bilingual, Plastic Welding, Power Tools, Assembly.

Description :

- Knows and understood all safety rules and precautions necessary for working in and about a manufacturing environment.

- Located and marked bending and cutting lines onto the workpiece.

- Checked work assignments and interpret blueprints and/or sketches to determine parts required.

- Responsible for measuring, marking, counting, and locating components on/in an assembly.

- Advised supervisor of any discrepancies in and/or shortages of required parts.

- Positioned sub-assemblies on parts using clamping devices and material handling equipment as required.

- Used necessary tools, measuring devices, templates, etc., to join up parts in accordance with blueprints and specifications maintaining allowable tolerances.

Experience

0-2 Years

Level

Entry Level

Education

Associate In Aeronautics